This was a very exciting project I was involved in recently – my friend lives on quite a large property that is filled with various agricultural equipment and tractors that have unfortunately been sitting outside for the best part of 30 years meaning the majority have become rusted and seized. One of these was a mini excavator that ran on a Honda GX240 engine that we decided we would take apart and rebuild in an attempt to get it running to hopefully sell in the future.

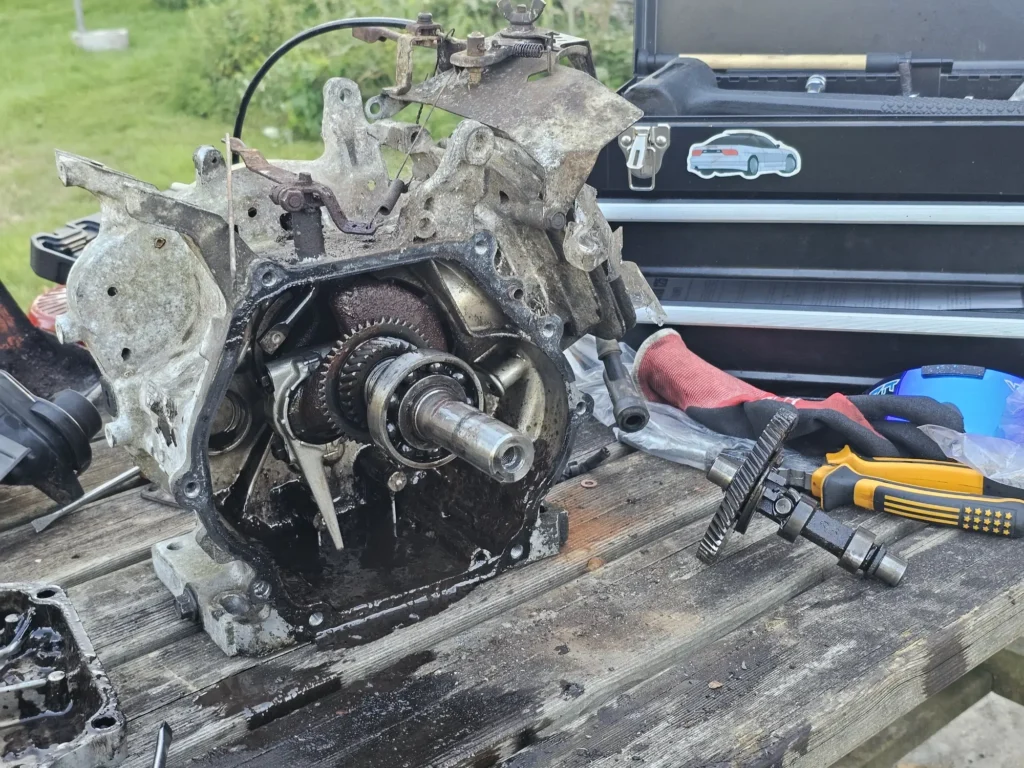

The engine wouldn’t start as expected. After compression testing and subsequent tear-down of the engine, we found the piston rings had seized as well as the crank seal & bearing had gone bad. With the engine taken apart, we cleaned the internals whilst waiting for the new piston rings and crankshaft seal to arrive. This allowed us to learn a lot through studying how everything worked inside the chamber etc.

Once everything had arrived and we cleaned the engine up as best as we could, it was time for reassembly. Unfortunately we didn’t have a press to fit the crank seal and bearing back on however in the end we did manage to do it using various tools. We had also left the bearing in the freezer overnight with intention of shrinking it just enough for us to fit it back into the crankshaft case which frustratingly began to warm up very quickly, making this a little harder.

We finally rebuilt the engine using the new parts along with the refurbished existing parts and after another compression test confirmed that the engine should now theoretically run. After attaching the carburettor and throttle assembly, we attempted to start the engine in the back garden however quickly realised the because the throttle & carb hadn’t been tuned since the rebuild, our safest bet would be to mount it back on the excavator whilst we make the final adjustments and break the engine in fully.

It took a while for us to tune the carb to a stable idle but it was very rewarding to see the engine running again! We learnt a lot whilst we were tuning the carburettor and definitely have a new appreciation for doing it without any electrical aids. Once we hooked it all back up and connected it to the hydraulic pump on the excavator, we fired her up again and to our relief we could hear the hydraulic pump working seamlessly.

We’re now just awaiting new hydraulic fluid and hydraulic filter before he hopefully bring this excavator back to life.